Inspection Planning

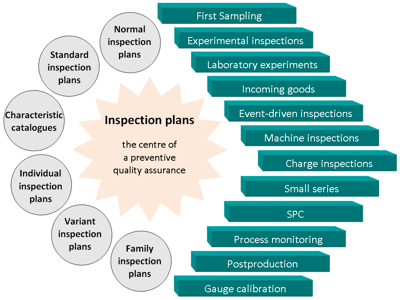

Inspection planning has a fundamental meaning for any preventive tests and inspections from laboratory experiments to incoming goods inspections. Using the iQ-PLAN module it is possible to collect any relevant information. By specifying the inspection task (type of inspection order) only the required presetting and control parameters are prompted.

The creation of inspection plans becomes even much easier if inspection characteristics are automatically taken from CAD drawings (see iQ-CAD-Interface).

Workflow

An inspection plan can be created in different ways. The classical approach is to use the structure as it is provided by iQ-PLAN. If the iQ-APQP module is available and has already been used to define a control plan then this plan can be used to derive an inspection plan from it. Changes in the control plan can be transferred to the derived inspection plan. As already mentioned another option is to use iQ-CAQ-Interface to automatically create an inspection plan from a two-dimensional CAD drawing. Changes in the drawing can then directly be used to create a new revision using the drawing comparison tool. After the inspection plan has been finished it will undergo a plausibility check and then be released. If this check results in failures that are not inspection relevant then a warning will be displayed whereas inspection relevant failures will prevent the release.

Important Features at a Glance

Unified inspection planning

for each type of quality inspections

(Laboratory) Experiments

(Laboratory) Experiments

- First sampling inspections

- Incoming goods inspections

- Event-driven incoming goods inspections

- Inspections during production for single part production, small series, series (SPC) and 100% inspections

- Inspections during mounting

- Goods issuing inspections

- Postproduction inspections

- Normal inspection plans for any kind of inspection order

- Standard inspection plans for referencing in a normal inspection plan (e. g. a normal inspection plan for a measurement based inspection with a referenced procedure from a standard inspection plan for material testing of any item of the same material)

- Individual inspection plans e. g. for a specific supplier

- Variant inspection plans e. g. for parts with the same shape but different measurements (such as screws with a differing length)

- Family inspection plans for identical inspections of different items

- Global inspection plans for test utilizing the knowledgebase of the inspector

- General description

- Assignment of material(s), the supplier and so on

- Management information such as the number of uses and the last usage

- As inspection plan history

- Overlapping validity periods

- Assignment of drawing folders or a drawing revision

- To reflect a changed construction

- Release or Blocking of a plan on revision level

- Combining characteristics that are inspected at the same location (measurements, material analysis, and functional checks) by specifying an inspection location group or a specific inspection work place

- Combining characteristics that are inspected in a sequential order (after milling, sawing, drilling, etc.)

- Defaults for collection of accompanying information while inspecting on a sample lot (charge, quantity, production data) or on single test items (serial number, machine, tool, nest) or of other data

- User-definable sampling procedures with any number of inspection severities and transitions for dynamic sampling

- AQL values

- Defaults for strongest and weakest inspection severity and specification of entry severity

- Statistical sampling defaults such as number of samples, sample size, inspection interval

- Guidance for collection of characteristic data during inspection for an optimized workflow such as control parameters for the sequence of inspections

- Entry of attributive and variable characteristics in one single form or a one-line overview (e. g. dimensional positioning within a drawing)

- Guidance for handling additional information

- Force to take notice of additional information for each characteristic (such as an instruction like connect pins 11 and 17 and measure between pins 11 and 6)

- Specification of events and actions in exceptional situations

- Mandatory text entry in failure situations

- Consideration of the knowledgebase of the inspector that has been built from previous experiences

- Characteristic catalogues; copying of recurring characteristic data

- Gauge type or unique ID of the gauge

- Weighting of the characteristic

- Drawings or drawing folders including information such as revision, sheet, cut, etc.

- Sampling data analogous to the inspection procedure; characteristic values take priority over the inspection procedure

- For variant inspection planning it is possible to change characteristic defaults, disable the originating variant or add a characteristic that is only relevant for the variant

- Group of failure types

- Group of failure locations

- Group of failure reasons

- Target value with upper and lower specification limit absolute or relative

- Nominal value with upper and lower deviation

- Absolute or relative dimensioning

- Static and dynamic action and warning limits

- Plausibility limits

- Tolerance tables for fit tolerances and further standards

- Characteristic relations

- Inspection programs for complex processes (e. g. for ovality)

- Several SPC defaults

- Capturing of data manually entered using the keyboard, semi-automatically using connected measuring devices or full-automatically from test facilities, etc.

- Classification for disposition of parts during production

- iQ-APQP as interface to the control plan

- iQ-CAQ-Interface for an automatical creation of an inspection plan from a CAD drawing

- iQ-PMV to manage gauges that are references in the inspection plan

- iQ-GL for a centralized maintenance of all master data that is relevant in other modules, too

- iQ-DOKU for further document management features

Types of inspection plans

Inspection plan structure

Header

Revision

Inspection procedure

Inspection characteristics

Common specifications for attributive and variable characteristics

Special attributive characteristics

Special variable characteristics

Interfaces to Other Modules